Research on organic, printed and flexible electronics, smart textiles, smart garments and environmental sensors for IoT applications. The core objectives cover printing and additive deposition of electronic structures using novel functional nanomaterials (metallic nanoparticles, organic conductive compounds, carbon nanotubes, graphene) and integration of electronic functionalities on flexible foils and in textiles. Particular attention is devoted to R&D on sensors for detection of humidity, temperature and various chemical gases and vapours based on electrochemical and chemoresistive principle.

Research team competencies and activities

The Materials Research team is well equipped with instrumentation and technical facilities needed for the additive manufacturing processes, rapid prototyping, deposition of functional materials as well measurement, diagnostics and testing of materials, components and electronic systems. The working group is focused primarily on three R&D domains which substantially overlap each other:

- Smart textiles.

- Printed, flexible and large-area electronics.

- Organic, printed and large-area sensors.

Smart textiles domain embraces following R&D activities:

- Interconnection and contacting systems on textiles (screen printed, embroidered, knitted, dismountable interconnections).

- Textile based sensors (temperature, humidity, strain and presence sensors), textile electrodes for continuous ECG and HR monitoring fabricated by embroidering or knitting technologies.

- Integration of functional electronic blocks into textiles and their encapsulation.

- RF communication (embroidered and screen printed antennas on textile substrates, WAN and BAN communication modules for IoT applications).

- Development of the smart textile product prototypes (smart firefighter protective suits, smart protective gloves and boots, smart bed sheets, clothing with integrated ECG textrodes).

- HW & SW prototyping of control, sensor evaluation, RF communication, data processing and visualization circuits.

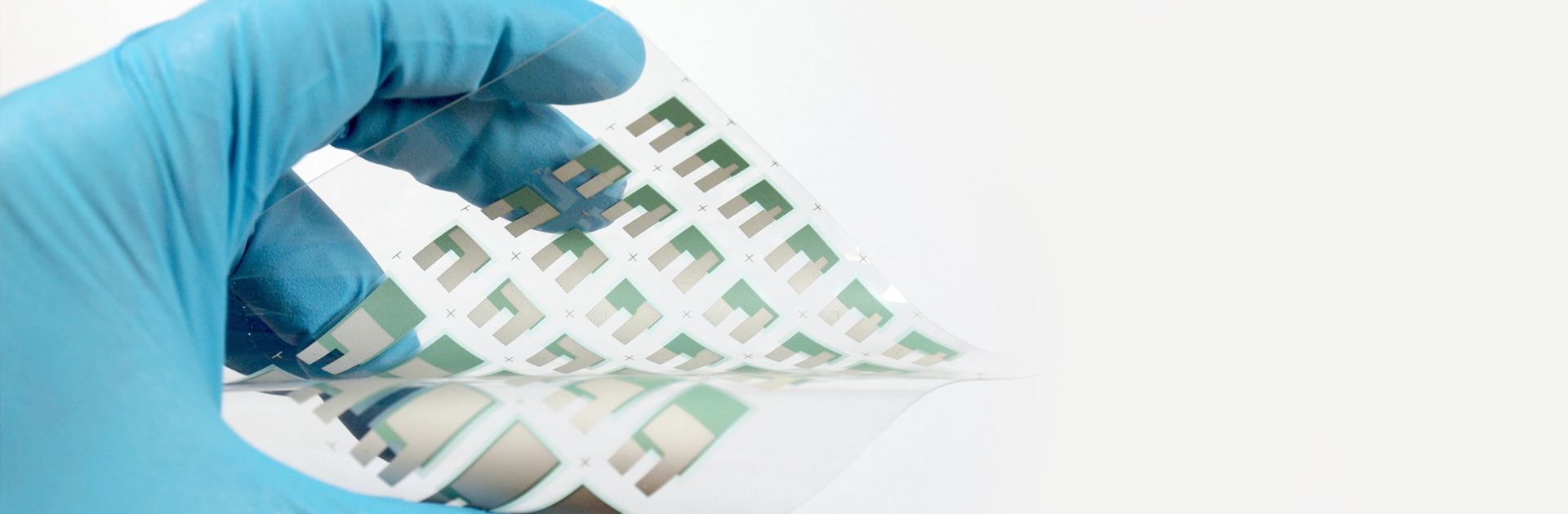

Printed, flexible and large-area electronics domain embraces following R&D activities:

- Contactless deposition of functional materials by the Aerosol Jet® 300 deposition system from Optomec equipped with two atomizers, laser sintering unit and plasma head. This activity is mainly focused on printing of antennas, conductive interconnections, passives and sensor structures on coarse, curved and flexible substrates. The Aerosol Jet Printing (AJP) is able to deposit lines widths down to 10 µm by mask-less selective printing technique which is suitable for rapid prototyping, printing of e.g. organic materials, CNTs modified by organic compounds, bioactive materials or special metal nanoparticle inks.

- Functional printing of antennas, conductive interconnections, passives, sensor structures using the semi-automatic screen printing machine Ekra E2 on unconventional substrates for electronics like flexible plastic foils, paper and textiles.

- Design and realization of electronic component structures produced by additive manufacturing technologies using organic and inorganic nanoparticle materials.

- Design and realization of power electronic components and modules based on Thick Printed Copper (TPC) technology including conductive interconnections, passives, multilayer structures and bare die bonding.

- HW & SW prototyping of control, evaluation, RF communication, data processing and visualization circuits.

Organic, printed and large-area sensors domain embraces following R&D activities:

- Design and realization of organic-based chemoresistive and electrochemical sensors for detection of specific gases (e.g. NO2, NH3, ethylene), sensor calibration and testing.

- Design and realization of printed and flexible sensors for detection of temperature and humidity including knitted and embroidered textile based large area sensors.

- Design and realization of sensors for in-situ monitoring of resin hardening and control system for the resin hardening processes.

- HW & SW prototyping of control, evaluation, data processing and visualization circuits for sensors.

The research team is fully equipped and well experienced for the above mentioned R&D domains and also benefits from close cooperation with the RICE Diagnostic team sharing the following in-house infrastructure and equipment: the microscope laboratory (confocal microscopy, fluorescence microscopy, AFM and SEM microscopy including EDX elemental analysis, X-ray Computer Tomography), the laboratory of structural analysis (DSC, TMA, TGA and FT-IR instruments), the laboratory for environmental testing (climatic chambers, shock chamber, vibration and corrosion chamber), electrical and mechanical testing lab (VA characterization, dielectric and electrochemical spectroscopy, RF measurement, electrical multichannel parametric characterization, high voltage measurements, pull off tests, bend tests, etc.) and solder testing lab (wetting balance solderability tester, vapor phase soldering and reflow soldering equipment).

Team members

Other members

prof. Ing. Miroslav Husák, CSc.

CTU Prague - MEMS technology